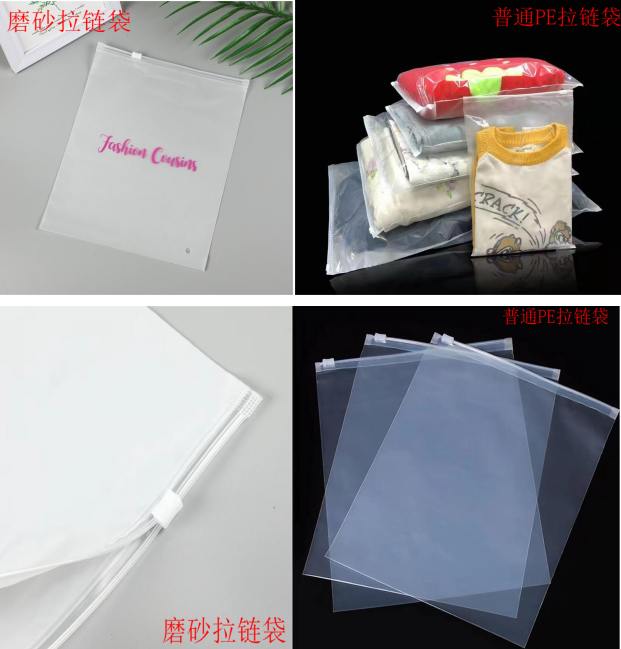

Sample bag display:

Main technical parameters:

|

Model |

YF-A900 |

|

Production Speed |

60-180PCS/min |

|

Bag-making width |

100-760mm |

|

Bag-making Length |

50-800mm |

|

Thickness |

0.03-0.3mm |

|

The speed of slider mounting |

200pcs/min |

|

Power Supply |

220V/380V |

|

Total Power |

7.5KW |

|

Overall Dimension(L*W*H) |

7.5*1.45*1.9m |

Main configuration list:

|

equence |

name |

Model |

Manufacturer |

quantity |

Warranty |

|

1 |

PLC (Upgraded) |

MZH2025 |

Ming Zhiheng electromechanical |

1 |

One-year warranty |

|

2 |

ultrasonic |

2500watts |

Jiarong |

1 |

One-year warranty |

|

3 |

Touchscreen display |

5 inches |

Ming Zhiheng electromechanical |

1 |

One-year warranty |

|

4 |

Main inverter |

1.5KW |

Kovo |

1 |

One-year warranty |

|

5 |

Discharging frequency conversion |

1.5kw |

Kovo |

1 |

One-year warranty |

|

6 |

Outfeed frequency conversion |

0.75kw |

Kovo |

1 |

One-year warranty |

|

7 |

Photoelectric eye |

|

Julong Optoelectronics |

1 |

One-year warranty |

|

8 |

Servo motor |

2.6kw |

Wade |

2 |

One-year warranty |

|

9 |

Magnetic particle tension |

2.5KG |

Ruihuan |

2 |

One-year warranty |

|

10 |

Proximity switches |

|

CITIC Electronics |

Several |

One-year warranty |

|

11 |

Turbomotors |

1.5KW |

Shanghai Henggong |

1 |

One-year warranty |

|

12 |

Geared motors |

1.5kw |

Expansion speed |

1 |

One-year warranty |

|

13 |

Compensating cylinders |

|

Bioge Pneumatics |

Several |

One-year warranty |

|

14 |

Solenoid valves |

|

Airtac |

Several |

One-year warranty |

|

15 |

Static Eliminator |

|

Haixian Electric |

1 |

One-year warranty |

|

16 |

Relays |

|

Xinling Electric |

Several |

One-year warranty |

|

17 |

Rubber rollers |

|

Yuanfeng customized |

4 groups |

One-year warranty |

|

18 |

Auto-tension |

|

Ming Zhiheng |

1 |

One-year warranty |

|

19 |

Fuselage racks |

|

Yuanfeng customized |

1 |

One-year warranty |

|

20 |

punch |

6mm |

Yuanfeng customized |

1 |

One-year warranty |

|

Remarks: The computer of this equipment adopts the latest upgraded version, the hot knife is the new hot knife, the deviation correction double magnetic particle control tension, two groups of servo motor traction, and the cylinder is used for automatic feeding for deviation correction. The equipment is equipped with automatic shutdown function for material breaking and automatic shutdown for zipper knotting. The above functions and features ensure the speed and stability of the equipment to the greatest extent, and at the same time facilitate operation. |

|||||